Global Professional PP Geotextile Products Solution Provider TW: Key Insights at Geosynthetics Conference

TAI'AN, SHANDONG, CHINA, December 25, 2025 /EINPresswire.com/ -- The modern civil engineering landscape is undergoing a significant transformation as infrastructure projects face increasingly complex environmental and structural demands. At the center of this evolution is the strategic implementation of advanced geosynthetics, which provide essential functions such as separation, filtration, reinforcement, and drainage.

The industry recognizes the critical role of pp geotextile products in extending the lifespan of roads, railways, and hydraulic structures. In this sector, China TW has established itself as a Leading Global Professional PP Geotextile Products Solution Provider. The core of their offering involves pp geotextile products, these materials, specifically non-woven polypropylene geotextiles, are engineered through a needle-punching process that creates a robust, permeable fabric. According to technical specifications for high-performance variants, these products feature excellent acid and alkali resistance, high tensile strength, and superior aging resistance, making them indispensable for soil stabilization and environmental protection in diverse geological conditions.

Navigating Structural Integrity and Environmental Challenges in Infrastructure

The global construction industry currently grapples with several persistent "pain points" that threaten the long-term viability of public works. One of the most significant issues is the contamination of aggregate layers. When soft subgrade soils mix with clean base materials under hydraulic pressure or traffic loads, the structural bearing capacity of the ground diminishes rapidly, leading to cracks, ruts, and eventual road failure. Furthermore, inadequate drainage systems often result in pore water pressure buildup, which can destabilize embankments and retaining walls.

Traditional methods of soil stabilization often rely heavily on expensive chemical treatments or the massive excavation of native soils, both of which carry high carbon footprints and logistical burdens. In coastal engineering and landfill management, the challenge is even more acute, as materials must withstand constant exposure to corrosive elements while maintaining their filtration efficiency. This is where high-quality pp geotextile products offer a more sustainable and cost-effective alternative. By providing a reliable barrier that allows water to pass while retaining fine soil particles, these solutions prevent the internal erosion that leads to sinkholes and slope failures.

The Evolving Geosynthetics Landscape and Industry Convergence

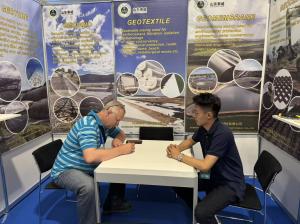

The outlook for the geosynthetics sector remains highly positive, driven by the global push for resilient infrastructure and green building standards. Analysts predict a steady rise in the adoption of synthetic liners and fabrics as governments prioritize flood control and efficient waste management. This growth is particularly evident at major industry gatherings like the Geosynthetics Conference, where experts gather to discuss the integration of smart materials and new installation techniques. The conference serves as a vital platform for showcasing how a pp geotextile products solution provider can bridge the gap between theoretical engineering and practical, on-site application.

During these international forums, the dialogue has shifted toward the "systemic approach" to civil engineering. Rather than viewing a geotextile or geomembrane as a standalone component, engineers are now focusing on how these materials interact within a composite system. The synergy between drainage boards, geogrids, and three-dimensional vegetation networks is essential for creating "living" infrastructures that can adapt to climate change. As the industry moves toward more rigorous testing standards, the demand for manufacturers who can provide comprehensive technical data and proven case studies has never been higher.

Engineering Excellence through Specialized Manufacturing

At the forefront of this technical movement is TW, a company that has built a reputation for specialized production and management of high-tier geosynthetics. With a sprawling operational capacity that includes advanced machinery and a dedicated technical team, the organization manages an impressive annual output, exceeding 20 million square meters of geotextiles and 10 million square meters of geomembranes and composite membranes. This scale of production ensures that even large-scale international projects can be supplied with consistent, high-quality materials without the delays often associated with smaller manufacturers.

The product portfolio extends well beyond basic fabrics. It encompasses a sophisticated range of geomembranes, drainage boards, geogrids, and three-dimensional composite drainage networks. For specialized ecological restoration, the company provides three-dimensional vegetation networks and glass fiber grids, alongside flexible water pipes and plastic blind ditches. This breadth of products allows for a holistic pp geotextile products solution provider approach, where the specific hydraulic and mechanical requirements of a project—whether it be a high-speed railway bed or a hazardous waste containment cell—can be met with a precision-engineered solution.

Core Advantages and the Path Toward Sustainable Engineering

The competitive edge of modern geosynthetics lies in the rigorous quality control and material science behind the manufacturing process. For pp geotextile products, the use of high-tenacity polypropylene fibers ensures that the material does not degrade when buried in alkaline soils or exposed to the biological activity common in wetlands. The superior friction coefficients of these products also enhance the interlocking mechanism between the fabric and the surrounding soil, providing the necessary lateral restraint to prevent lateral spreading of the base course.

Looking toward the future, the focus is shifting toward the development of even more durable and environmentally neutral materials. The goal is to provide a pp geotextile products solution provider service that emphasizes the "total life cycle" of a project. This involves not only the initial supply of materials but also technical support in selecting the correct mass per unit area and tensile strength for specific load-bearing requirements. By optimizing material usage, engineers can reduce waste and ensure that the infrastructure remains functional for decades with minimal maintenance.

The commitment to innovation is reflected in the ongoing expansion of production lines and the refinement of composite materials that combine the functions of multiple geosynthetics into a single layer. As the global community continues to invest in sustainable development, the role of high-performance pp geotextile products will only become more central to the safety and efficiency of our built environment.

For more information on TW’s technical specifications and project applications, please visit: https://www.twgeo.com/.

The industry recognizes the critical role of pp geotextile products in extending the lifespan of roads, railways, and hydraulic structures. In this sector, China TW has established itself as a Leading Global Professional PP Geotextile Products Solution Provider. The core of their offering involves pp geotextile products, these materials, specifically non-woven polypropylene geotextiles, are engineered through a needle-punching process that creates a robust, permeable fabric. According to technical specifications for high-performance variants, these products feature excellent acid and alkali resistance, high tensile strength, and superior aging resistance, making them indispensable for soil stabilization and environmental protection in diverse geological conditions.

Navigating Structural Integrity and Environmental Challenges in Infrastructure

The global construction industry currently grapples with several persistent "pain points" that threaten the long-term viability of public works. One of the most significant issues is the contamination of aggregate layers. When soft subgrade soils mix with clean base materials under hydraulic pressure or traffic loads, the structural bearing capacity of the ground diminishes rapidly, leading to cracks, ruts, and eventual road failure. Furthermore, inadequate drainage systems often result in pore water pressure buildup, which can destabilize embankments and retaining walls.

Traditional methods of soil stabilization often rely heavily on expensive chemical treatments or the massive excavation of native soils, both of which carry high carbon footprints and logistical burdens. In coastal engineering and landfill management, the challenge is even more acute, as materials must withstand constant exposure to corrosive elements while maintaining their filtration efficiency. This is where high-quality pp geotextile products offer a more sustainable and cost-effective alternative. By providing a reliable barrier that allows water to pass while retaining fine soil particles, these solutions prevent the internal erosion that leads to sinkholes and slope failures.

The Evolving Geosynthetics Landscape and Industry Convergence

The outlook for the geosynthetics sector remains highly positive, driven by the global push for resilient infrastructure and green building standards. Analysts predict a steady rise in the adoption of synthetic liners and fabrics as governments prioritize flood control and efficient waste management. This growth is particularly evident at major industry gatherings like the Geosynthetics Conference, where experts gather to discuss the integration of smart materials and new installation techniques. The conference serves as a vital platform for showcasing how a pp geotextile products solution provider can bridge the gap between theoretical engineering and practical, on-site application.

During these international forums, the dialogue has shifted toward the "systemic approach" to civil engineering. Rather than viewing a geotextile or geomembrane as a standalone component, engineers are now focusing on how these materials interact within a composite system. The synergy between drainage boards, geogrids, and three-dimensional vegetation networks is essential for creating "living" infrastructures that can adapt to climate change. As the industry moves toward more rigorous testing standards, the demand for manufacturers who can provide comprehensive technical data and proven case studies has never been higher.

Engineering Excellence through Specialized Manufacturing

At the forefront of this technical movement is TW, a company that has built a reputation for specialized production and management of high-tier geosynthetics. With a sprawling operational capacity that includes advanced machinery and a dedicated technical team, the organization manages an impressive annual output, exceeding 20 million square meters of geotextiles and 10 million square meters of geomembranes and composite membranes. This scale of production ensures that even large-scale international projects can be supplied with consistent, high-quality materials without the delays often associated with smaller manufacturers.

The product portfolio extends well beyond basic fabrics. It encompasses a sophisticated range of geomembranes, drainage boards, geogrids, and three-dimensional composite drainage networks. For specialized ecological restoration, the company provides three-dimensional vegetation networks and glass fiber grids, alongside flexible water pipes and plastic blind ditches. This breadth of products allows for a holistic pp geotextile products solution provider approach, where the specific hydraulic and mechanical requirements of a project—whether it be a high-speed railway bed or a hazardous waste containment cell—can be met with a precision-engineered solution.

Core Advantages and the Path Toward Sustainable Engineering

The competitive edge of modern geosynthetics lies in the rigorous quality control and material science behind the manufacturing process. For pp geotextile products, the use of high-tenacity polypropylene fibers ensures that the material does not degrade when buried in alkaline soils or exposed to the biological activity common in wetlands. The superior friction coefficients of these products also enhance the interlocking mechanism between the fabric and the surrounding soil, providing the necessary lateral restraint to prevent lateral spreading of the base course.

Looking toward the future, the focus is shifting toward the development of even more durable and environmentally neutral materials. The goal is to provide a pp geotextile products solution provider service that emphasizes the "total life cycle" of a project. This involves not only the initial supply of materials but also technical support in selecting the correct mass per unit area and tensile strength for specific load-bearing requirements. By optimizing material usage, engineers can reduce waste and ensure that the infrastructure remains functional for decades with minimal maintenance.

The commitment to innovation is reflected in the ongoing expansion of production lines and the refinement of composite materials that combine the functions of multiple geosynthetics into a single layer. As the global community continues to invest in sustainable development, the role of high-performance pp geotextile products will only become more central to the safety and efficiency of our built environment.

For more information on TW’s technical specifications and project applications, please visit: https://www.twgeo.com/.

Shandong Taiwei Engineering Materials Co., Ltd.

Shandong Taiwei Engineering Materials Co., Ltd.

+86 196 0538 3580

taiwei@cngeosynthetics.com

Visit us on social media:

Facebook

YouTube

TikTok

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.